Are you responsible for a Flare-Stack, Transmission Mast or Other Guyed Structure? Have you suffered from the following problems & frustrations?

You were being pushed to get the structure back on-line and receiving complaints about the rising costs as a result of delays; the production department was complaining about the loss of production or the service controller about the disruption to telecommunications services but:

- There were too many people wanting to work on the installation at the same time.

- You could not progress one job because of the danger created by an adjacent job.

- Bad weather stopped men from going aloft and stopped cranes working.

- The wind was in the wrong direction bringing toxic fumes from an adjacent plant.

- The safety team was not happy about one or more of the above issues and stopped the job.

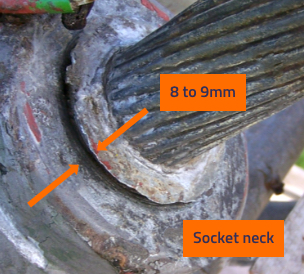

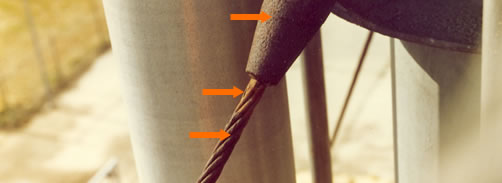

- You found an unknown problem with a guy rope and this created more delay.

In hindsight...

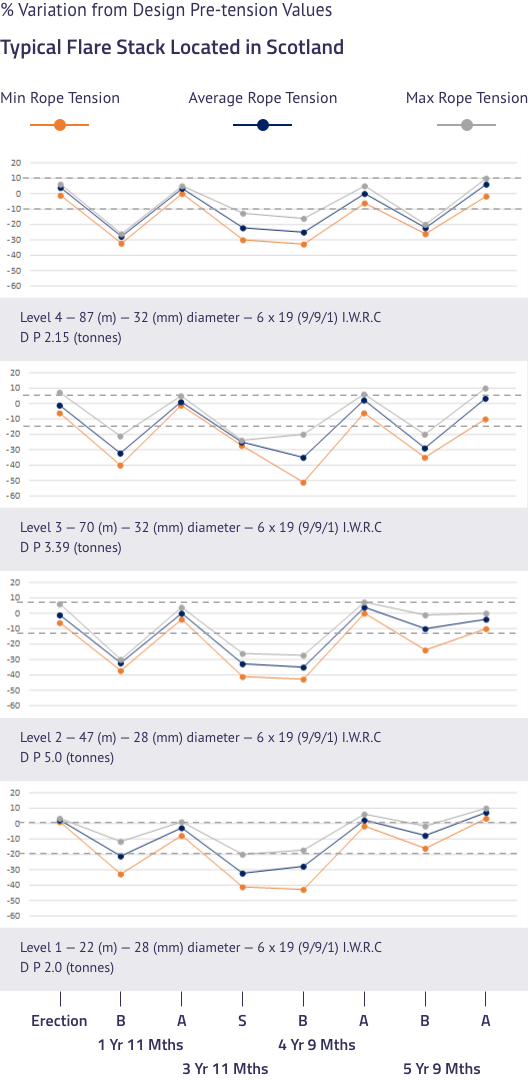

Wouldn't it have been useful if the guy ropes had been examined and 'greased' before the shut down started; and if you had known about the problem with that guy rope in advance?

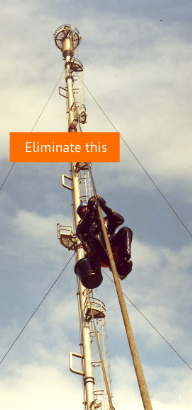

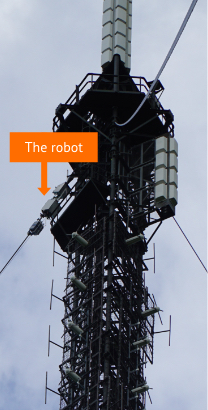

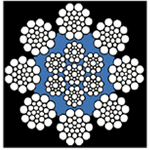

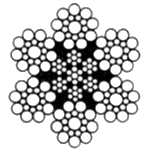

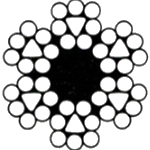

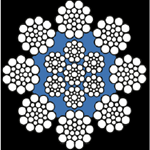

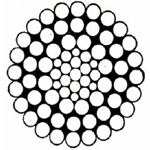

The solution? The Ropetech Robot

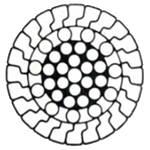

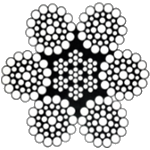

Deploy the Ropetech Robot together with Ropetech's know-how and you can carry out guy rope / stay rope condition assessment, and provide corrosion protection, without a shut-down.

If the answer to any of the above is yes; the solution is to talk to Ropetech

Contact Us